Using Diamond Grinding Cup Wheel is the most efficient way to grind from marks and imperfections in concrete, as well as masonry, stone and other vonstruction materials. This single row cup whell is designed for fast removal rates and long lifespan.

Features:

1. Diamond Cup Wheel is ideal for beveling, smoothing and shaping

2. The high diamond concentration provides for a faster cut rate while the high quality of the diamonds provides longer blade life.

3. Grinding segments with heat treated steel bodies which provide increases durability and grinding life.

4. Venting holes for fast, dry or wet grinding with long life.

5. Suitable for use on grinding on marble, tile, concrete, and rock.

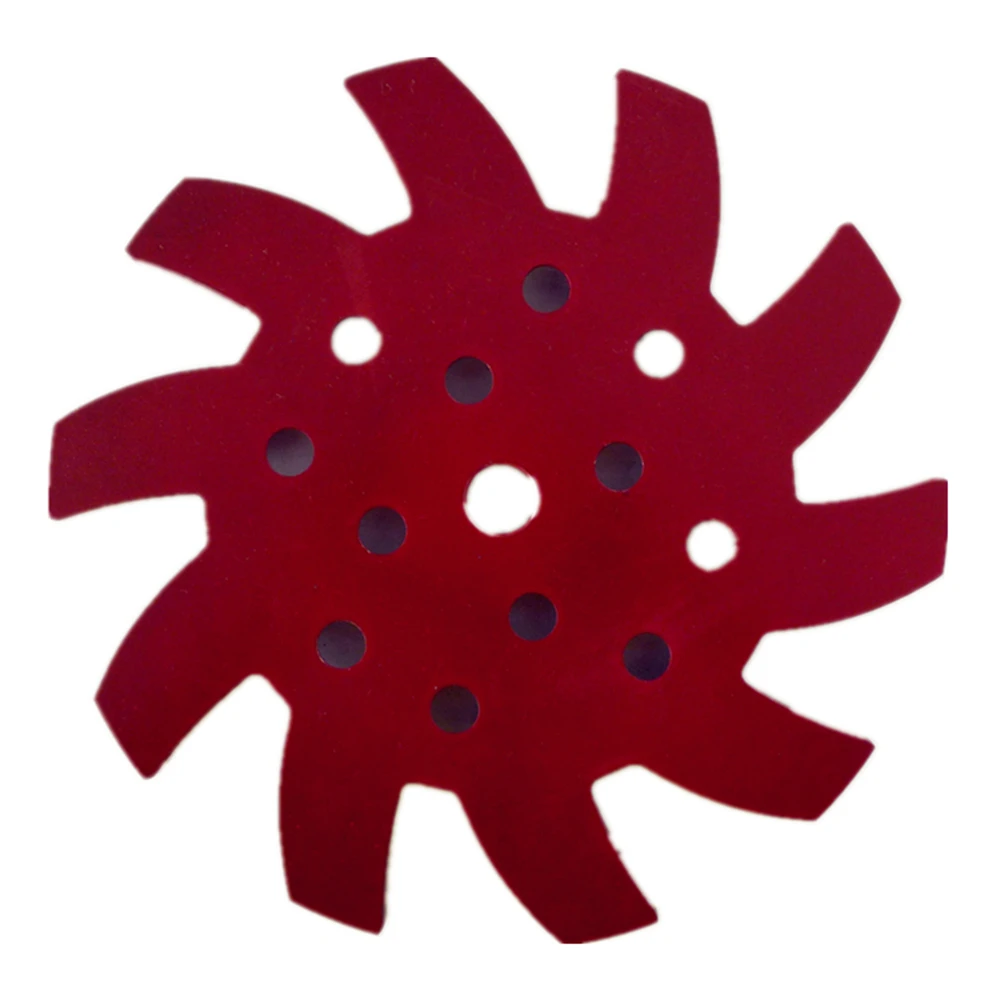

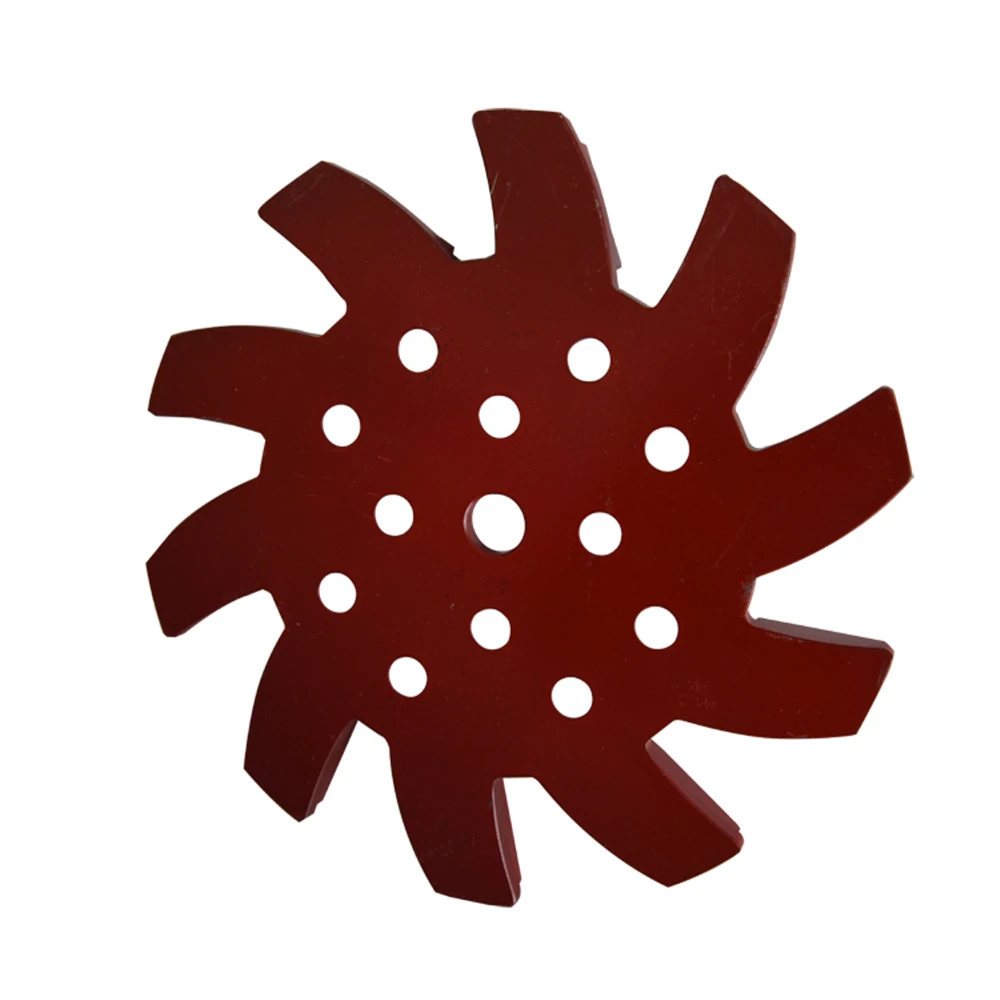

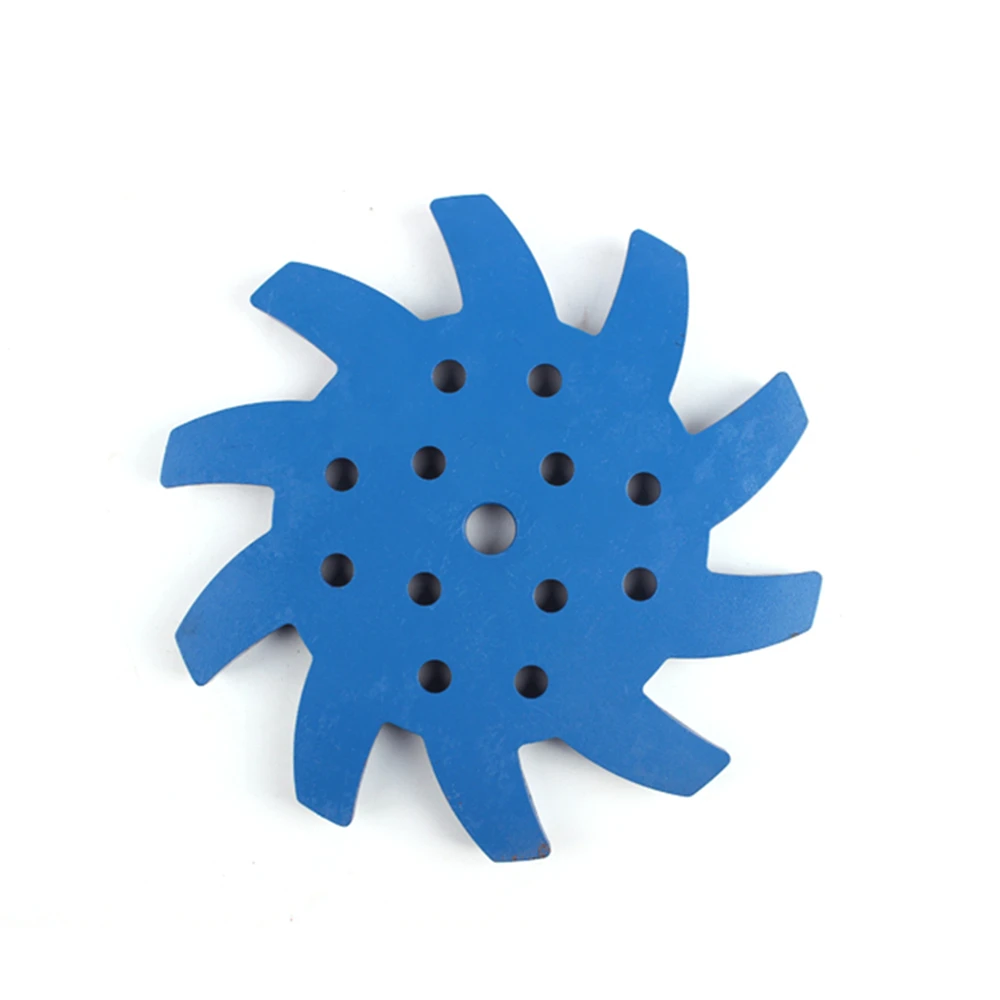

Product Name: D250mm 10 Inch Universal Diamond Grinding Cup Wheel with Twenty Arrow Shape Grinding Segments for Concrete Floor

Segments Material: Diamond Segments + 10 Inch Metal Blank

Diameter: 10 Inch (D250mm)

Segments Sizes: 24*14*8mm*20T (Twenty Arrow Shape Grinding Segments)

Bond Available: Soft Bond, Medium Bond, Hard Bond

Grits Available: Coarse, medium, fine ( grits 16- 270#) as requested

Metal bond diamonds have high strength, excellent wear resistance, and a low friction coefficient. Metal bond diamonds high grinding efficiency and low grinding force generates less heat in the grinding process.

1) Coarse grit: 16#,24#,25#,30# etc.

Could be used for un-even concrete floors , rough grinding preparation on floor or old floor renovation .

2)Medium grits: 36#, 50/60# , 60/80# etc.

Could be used for all kinds of concrete and terrazzo floors , grinding preparation on floor or old floor renovation.

3) Fine grits: 80/100# , 100/120#, 120/150#, 200# etc.

Could be used for all kinds of concrete and terrazzo floors , find grinding preparation on floor or old floor renovation before polishing.

Process: Cold Pressed Sintered, High-Frequency Welded

Surface Finishing: Color Painting

Applications: Granite, marble, concrete products, masonry material and all types of natural stone.

Machine: General Grinding Machine.

Advantages:

1. The high diamond concentration provides for a faster cut rate while the high quality of the diamonds provides longer blade life.

2. Grinding segments with heat treated steel bodies which provide increases durability and wheel life.

3. Venting holes for fast, dry or wet grinding with long life.

Quality Control:

1. Strict Raw material inspection

2. Professional formula

3. Production process control(PDCA+7S Principle)

4. Do some cutting testing to sure the using function

5. Products pass ISO9001 and SGS inspection

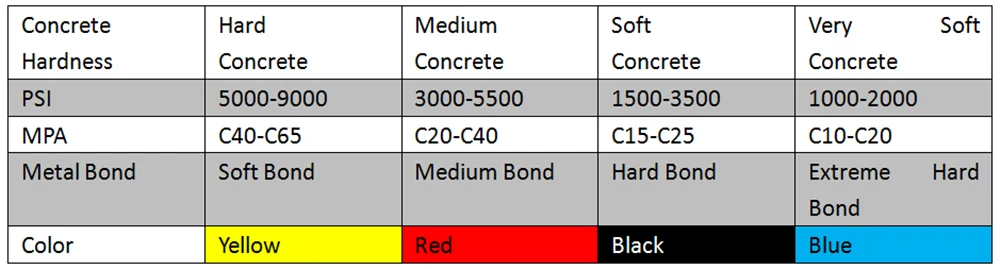

Choosing between soft, medium, and hard bonds.

Soft Bond (Yellow) – The metallic powder in the sintered segment wears away quickly releasing dull diamond crystals exposing new abrasive crystals to cut efficiently. Best used on hard surfaces.

Medium Bond (Red) – A metal bond strength right between that of soft and hard bonds.

Hard Bond (Black) – The bond of the metallic powder in the segment wears away slowly and prevents premature wear against soft, abrasive surfaces.

FAQ

Q: What is the MOQ?

A: The MOQ is 3 PCS

Q: What about the Lead Time?

A: For 1-10 Sets, the Production Time is about One Week. Mass Production Time is Need about 1-2 Weeks.

A: Yes. Please inform us formally before our production.

Q: How do you ship the goods and how long does it take to arrive?

A: For Not More Than 2 KG, We Usually Ship by China Post Air Mail or ePacket, It need about 10-25 Days. And for More Than 2 KG, We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-5 days to arrive. Airline and sea shipping also optional.